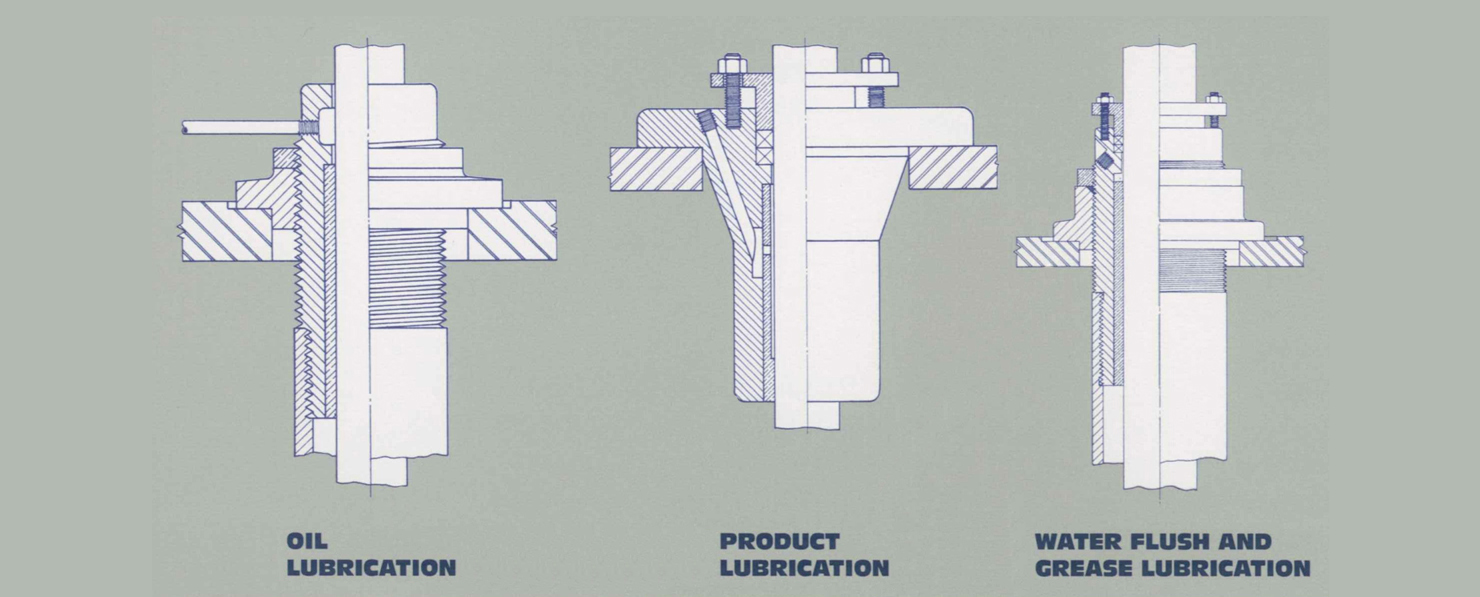

Standard pumps are designed for oil lubrication and are equipped with an oil reservoir, solenoid valve and needle valve. This assembly is connected to the tension nut body by tubing which allows the oil to gravity flow into the tension nut body bushing and down the lineshaft to lubricate each lineshaft bearing and the upper discharge bowl bearing. The lower discharge bowl bushing is lubricated by a mixture of oil and the water being pumped. The discharge bowl incorporates a bypass port to act as a drain for excess oil and pressure relief for the enclosing tube. The suction bowl is provided with a pocket below the bushing and is packed with non water soluble grease and provides lubricant for that bushing. As an option, a grease line running from the baseplate to the suction bowl pocket can be furnished for ease of maintaining bushing lubrication.

There are other means of lubricating pump bearings. Lubrication methods available include product, positive water flush and grease (manual or automatic). Pump construction will differ depending on lubrication selected. The condition of the water to be pumped will dictate the optimum lubrication system. When pumping clear water, oil or product lubrication is sufficient. Under severe conditions with abrasives, a positive water flush or grease lubricant is more appropriate. Consult the factory if help is needed to decide an appropriate lubrication system for a given application.

We also offer many different materials of bushings and bearings. Our standard material is Bronze. Other materials for bushings and bearings include Non-Metallic Back Marine Bearings, Bronze Backed Marine Bearings, Teflon, Ryertex, Cast Iron, Graphalloy, and other customer specified materials.